Recently we have Solza.nl Introduced the new revolution on the floor market in collaboration with the Dutch flooring brand Floer: Hybrid Hout! But how is hybrid wood actually built now, what makes these floors so special and how can you actually lay it best? Do you go for floating or for gluing these Hybrid wood flooring ? In this blog we delve deeper into all these issues. Very handy!

The build-up of hybrid wood floors

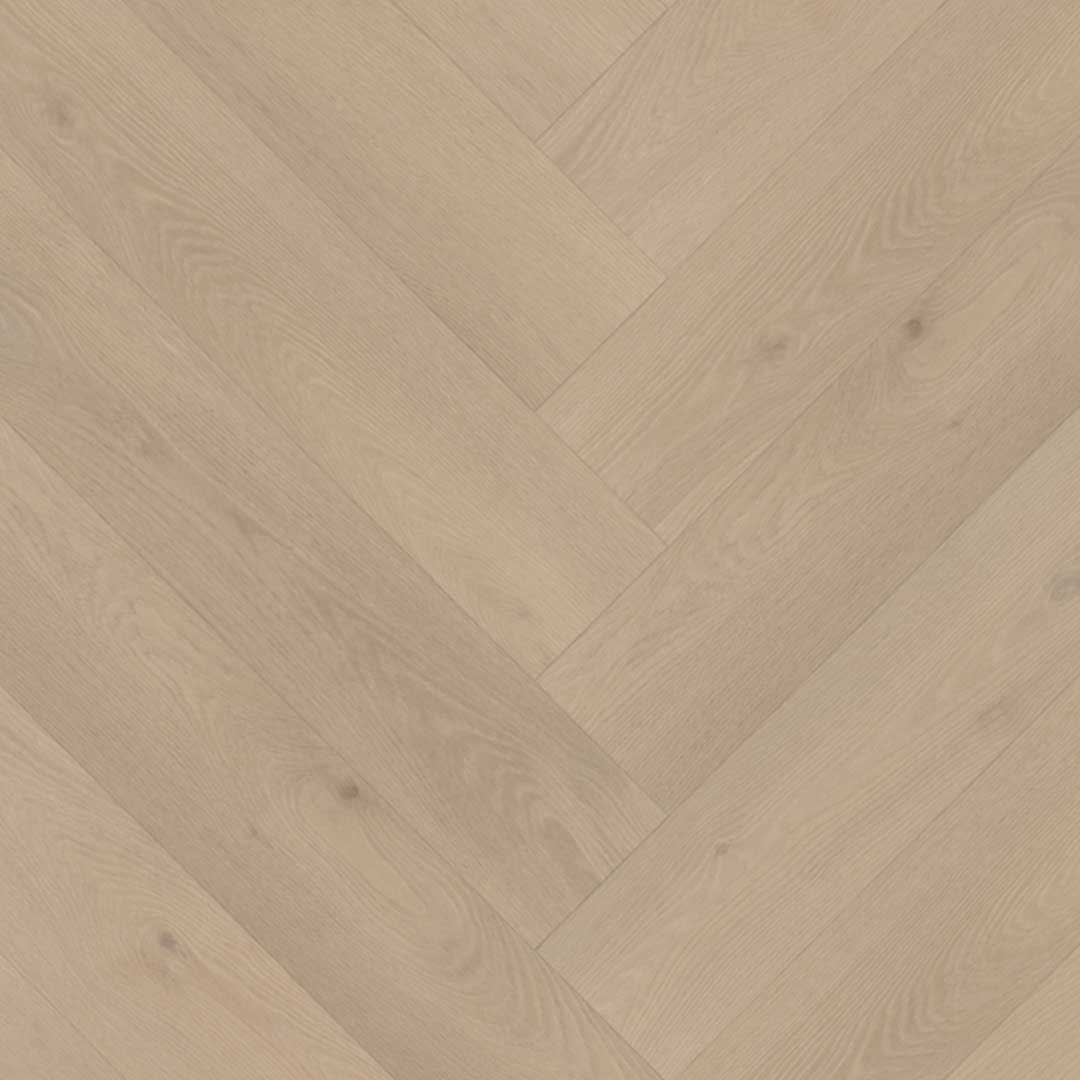

This type of flooring involves a combination of different materials. In the case of a hybrid wooden floor, it usually consists of several layers, combining a top layer of real wood with other materials such as HDF. The top layer of real wood, also called the wear layer, is usually produced from oak.

The combination of real wood and other materials in a hybrid wooden floor results in a floor with some advantages. It is more durable than solid Wood flooring , Because it is more resistant to moisture and temperature changes. In addition, these floors are more affordable than solid wood, while still maintaining the warmth and natural appearance of wood.

The underlying layers, made of HDF, provide stability and durability to the floor. They help to make the floor resistant to moisture, temperature changes and wear. These layers can also help prevent warping or shrinking of the floor. In addition, thanks to this unique plank structure, you can easily lay these floorboards as we are used to from, for example Laminate .

The Hybrid wood floors of Floer Namely, have a click system for the installation, which means that the boards can be easily snapped together without the use of glue. This makes the installation simple and also possible dismantling and reuse.

Gluing hybrid wood or floating laying?

Laying hybrid wood floors can be done both floating and glued , Depending on various factors. Here are some considerations to determine which installation method is most suitable:

- Underfloor: A glued installation usually requires a suitable subfloor, which is sufficiently flat and even. If the existing subfloor is not suitable for a glued installation, floating placement may be a better option. For this, a suitable Subfloor To be applied under the Oak wood floor .

- Underground: The type of surface can also be decisive. A concrete subfloor is more suitable for gluing, while a wooden subfloor may be more suitable for a floating installation.

- Noise Reduction: If noise reduction is important, a floating installation may be preferred, because the Damping subfloor Helps reduce walking noises. There are special subfloors available which are certified for noise reduction to undersections such as contact sound reduction, for example choose the 10 dB Floer Noiseless Or Floer Contactless Subfloor . Bonding can also ensure better noise reduction, but specialist products should be used for this, which are often very expensive.

- Stability: Gluing generally offers a more stable floor and more massive running noise, as the boards are attached directly to the subfloor. Floating floors may have some flexibility, which may have advantages in temperature and humidity fluctuations.

Thanks to the handy click connection, the floors are relatively easy to place, which means you can save high laying costs. Do you opt for gluing, right? Then that is not a problem either, but this is often a more laborious and expensive job.

Always follow instructions from, for example, Floer

For proper processing, always follow the manufacturer's installation instructions. They can provide specific guidelines and recommendations for the best installation method based on the product you are using.

Curious about Hybrid wood? Visit our showroom!

Do you want to see these floors in real life? Then come visit us in the Showroom located in Alphen aan den Rijn Or easily order a sample via our website and experience the floor in real life. Do you still have questions about this revolutionary new type of floor? Then reassure these to our floor experts. We are happy to help!